Model MDC10-TUCM

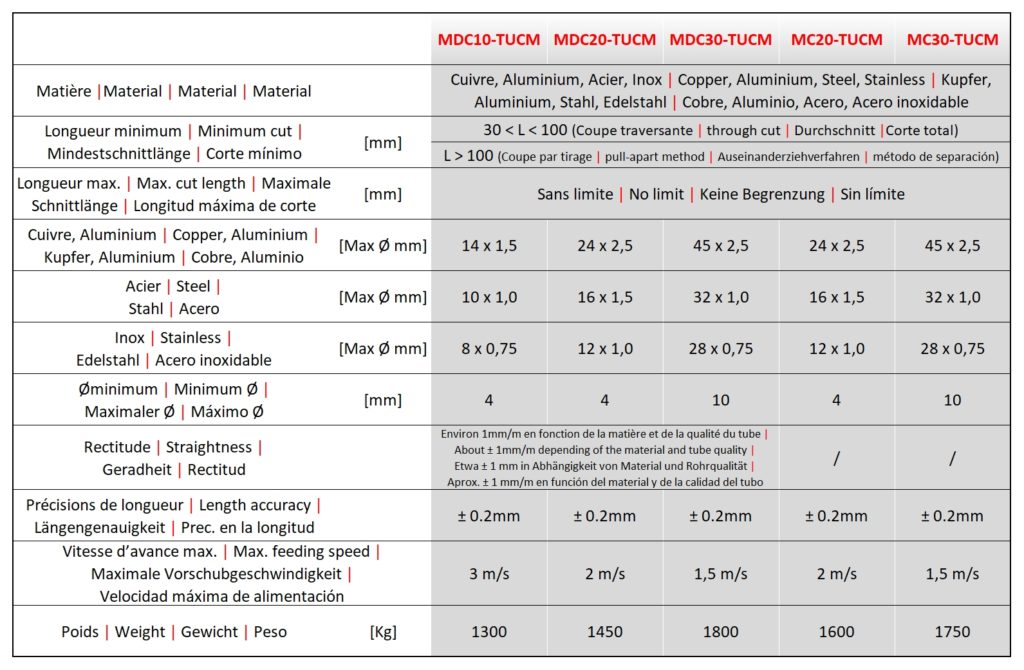

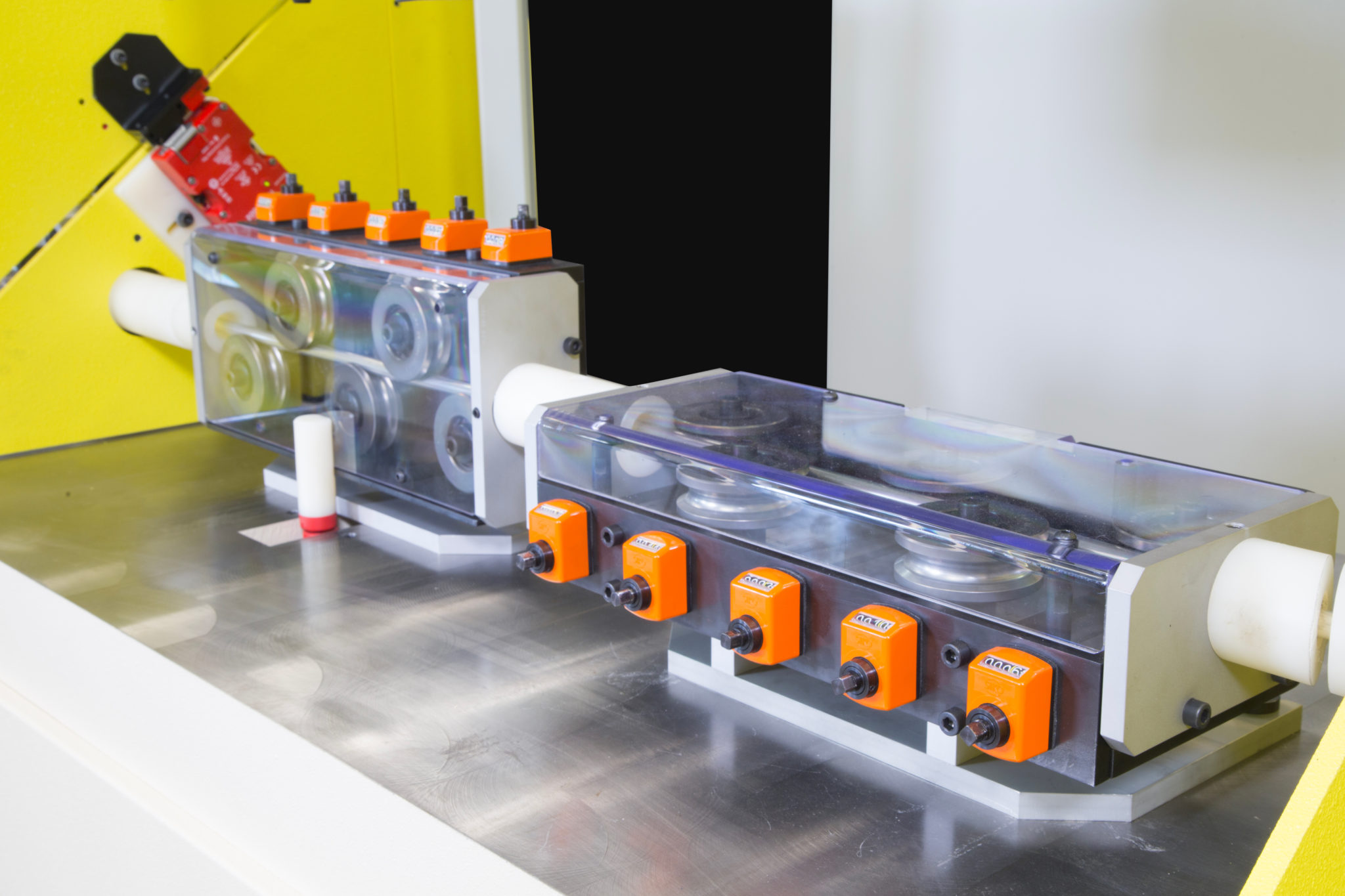

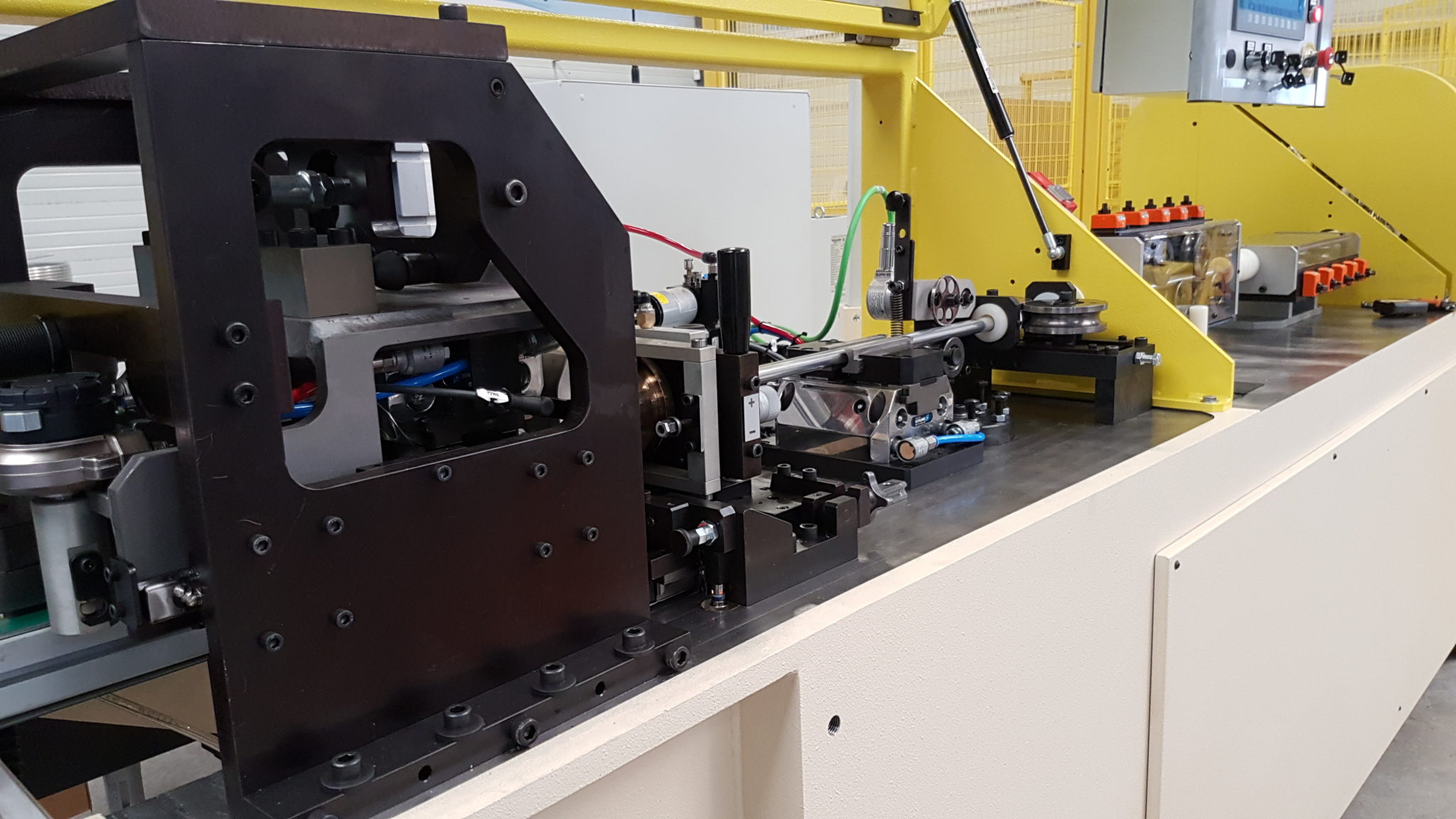

The range of tube cut-off machines consists of the MDC10 TUCM, MDC20 TUCM and MDC30 TUCM models. Chipless orbital cut-off technology as opposed to saw cutting, avoid the chips, and so material losses and the need for tube washing. It significantly reduces cycle times. In order to procure a perfectly controlled cut, two stages are required: first, the cutting wheel penetrates to 95% of the thickness of the tube; next, lateral traction is provided by means of a pulling station. Depending on the power source applied (pneumatic or hydraulic), the diameter reduction can be close to zero. In many cases, it is no longer necessary to deburr the tube ends before bending operations with the mandrel. All the advantages of this technology are enhanced by the powerful devices installed on RAVNI tube cuts, including digital belt-drive feed systems enabling speeds of 180m/min with an accuracy of ± 0.2mm.

Ravni Technologies has equipped its cutting unit with a brushless servo motor to control the plunge movements of the wheel. All the parameters to obtain the ideal quality for each customer requirements are available on the touch control panel.

To meet the needs of the most demanding customers, quick-change tool systems have been developed (belts, jaws, cutting tools, straighteners). These machines are used in the automotive sector (brake tube, diesel, air conditioning), aeronautics, heat exchangers, etc. The highly modular design of the RAVNI cutters and straighteners supports customisation through, for example, the integration of deburring, marking and laser or ultrasound control machines. Ravni has also developped a range of chipless orbital cutting machines (MC20 TUCM andMC30 TUCM) for tubes in bars.

Descriptif complet

Une question ?

Une question ?